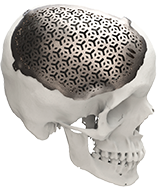

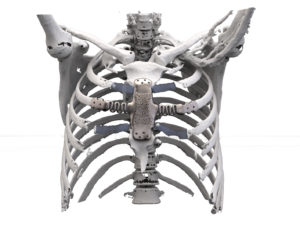

CMF

We know that each patient presents unique challenges in their treatment. Our focus is to develop solutions that restore functionality and aesthetics to your patients.

The collaborative work with the surgeons allows us to provide the necessary products so that each patient receives the optimal treatment.

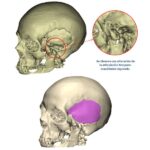

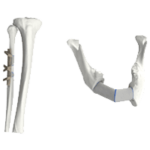

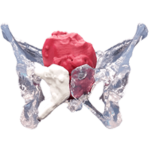

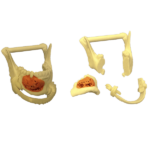

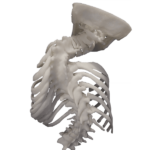

Patient specific implant for TMJ reconstruction

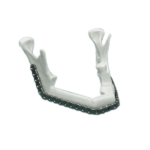

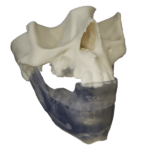

Patient specific implant for TMJ reconstruction  Patient specific implant for segmental jaw reconstruction

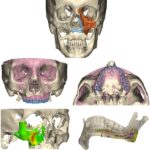

Patient specific implant for segmental jaw reconstruction  Patient specific facial augmentation

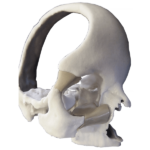

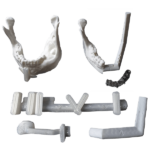

Patient specific facial augmentation  Patient specific guides for maxillary reconstruction with microvascularized fibula

Patient specific guides for maxillary reconstruction with microvascularized fibula  Splints for orthognathic surgery

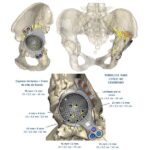

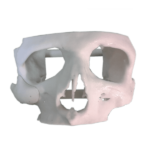

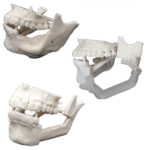

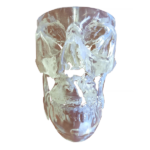

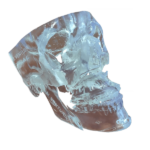

Splints for orthognathic surgery  Biomodels

Biomodels

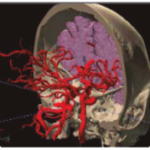

3D Planning

3D Planning  Surgical Navigation

Surgical Navigation  Intra-Surgical Assistance

Intra-Surgical Assistance