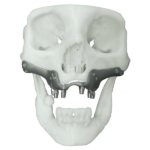

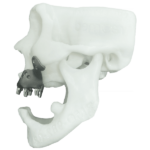

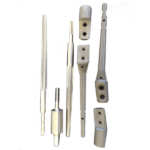

Design and Manufacturing of patient specific implants

The concept of custom-made implants proposes a paradigm shift for medical implants, where prostheses are adapted to the patient's anatomy, while traditional or standard prosthesis systems postulate adapting the patient's anatomical structures.