TITANIUM

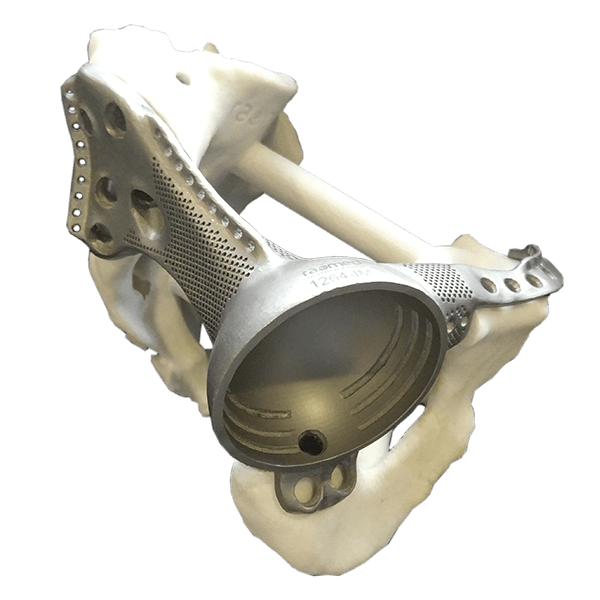

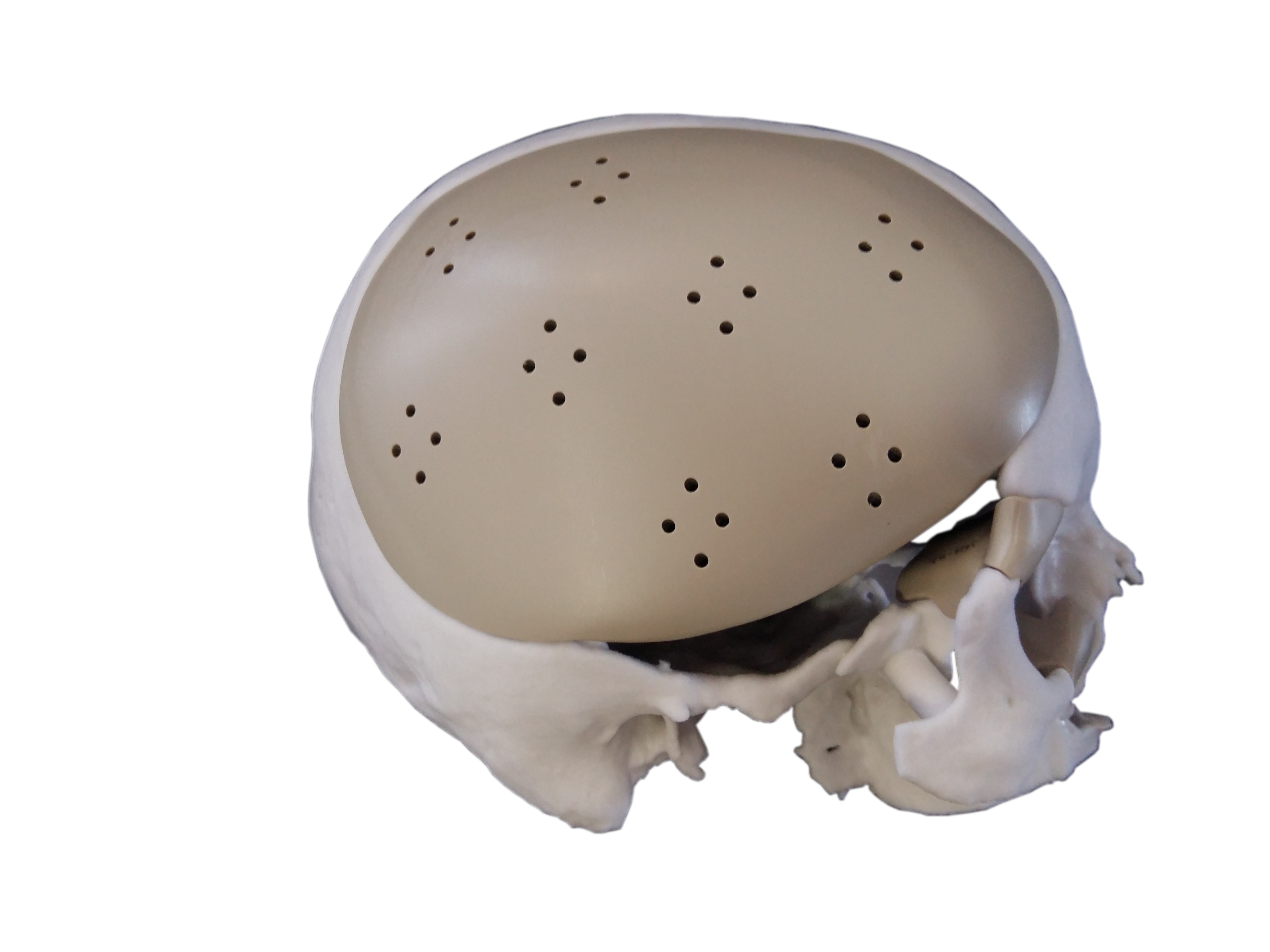

Raomed has the latest technology in Titanium manufacturing. Additive manufacturing (3D printing) of Titanium alloy grade 5 (Ti64).

The additive manufacture of Titanium makes it possible to create porous structures, which mimic the bone of the implant's host, enabling its osseointegration.

Trabecular structures substantially reduce the risk of stress shielding and improve the mechanical performance of the implants.