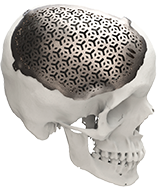

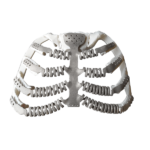

Thorax

Raomed is a company founded on innovation, and is continuously proposing new solutions to solve the needs of its surgeons and patients. In this section you will find new concepts of patient specific implants and surgical guides applied to the thoracic area.

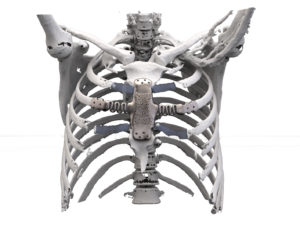

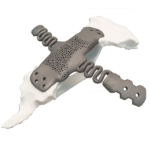

Patient specific implant for sternum and ribs

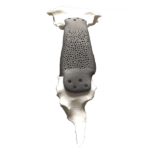

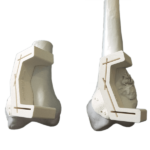

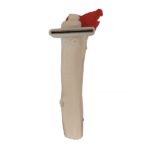

Patient specific implant for sternum and ribs  Patient specific resection guides

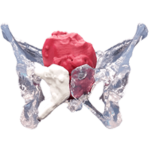

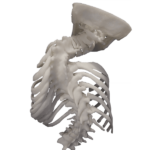

Patient specific resection guides  Biomodels

Biomodels

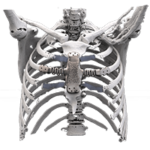

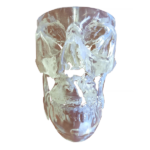

3D Planning

3D Planning  Surgical Navigation

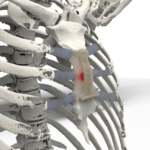

Surgical Navigation  Intra-Surgical Assistance

Intra-Surgical Assistance